How much horsepower is in a horse? A LOT!!!!!

🚗 Testing cars and accelerating from 0 to 100 km/h in under 5 seconds, I finally have the opportunity to compare it to horseback riding 🐴. I won’t reach 100 km/h on a horse, but thanks to that, I also have a different sense of speed and dynamics.

Oh, this automotive industry…

Subcontractor-Tier 2, supplier-Tier 1, and finally OEM. When I was a student, I dreamed of becoming an engineer who develops cars. The path to this goal was winding. For some time now, I have been working on cars, and soon these cars will premiere in Poland!

Vibroacoustic engineering in automotive

Global organizations are forcing the construction of increasingly fuel-efficient cars, reducing the consumption of natural resources. Usually meeting such requirements leads to optimization of car design. Very often it concerns the generation of noise, which can sometimes be a nuisance when driving a car.

Noise becomes a real problem for the end customer and is cascaded by car corporations throughout the supply chain. As a result, OEMs are changing their cars, and suppliers and sub-suppliers must also follow developments imposed from above.

Intuitive creative process vs algorithms

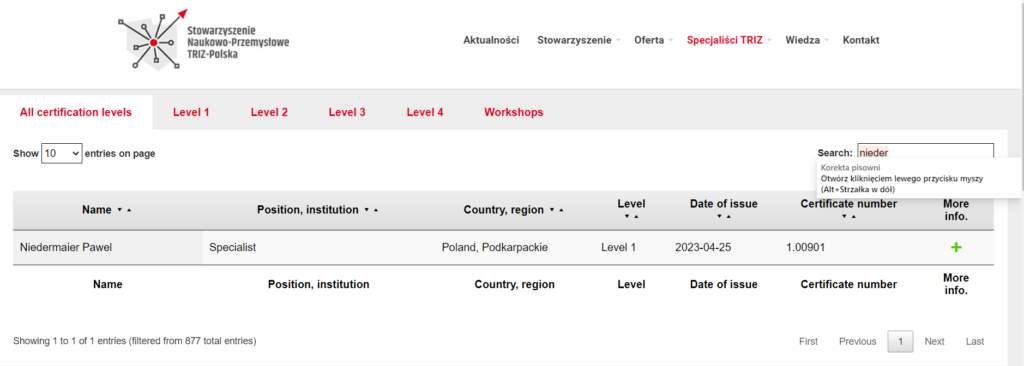

🥱 Bored with “Lean” and “Six Sigma” – methods common in Automotive, I was looking for knowledge on how to approach problem solving innovatively. Methodological optimization and “nibbling” percentages is not always the right solution, when it’s begging to be “turned upside down”. My creative approach in problem solving was ‘somehow’ intuitive, based on ‘some’ experience, being ‘somehow’ more open to solutions and ‘somehow’ having flashes of ideas. Often this approach led me to come up with ‘some’ solution. However, I was also often left with an idea and the thought “what next?”.

As NVH engineer I tested at least 21 models of cars

I have had the opportunity to test the noise and vibration (nvh) of many different cars, at different stages of development. Some were early prototypes and others were series cars.

I bought a car trailer for $110k and implemented it to NVH process

Towing dyno – is a car dyno in the form of a trailer. The load it generates is able to stop the car in a fraction of a second. I drove the car myself, took care of the trailer and took measurements of vibroacoustic. For NVH Engineer towing dyno substitutes hills.

Designed in Rzeszów, Made in Germany

The automotive business looks like that in Germany they have research and development of products, and in Poland these products are manufactured. In this post I describe an interesting example showing the reverse trend in the automotive industry. Polish doesn’t mean it’s worse…

Vehicle nvh engineering

Vehicle nvh engineering is my passion. I did nvh measurements on brand new luxury car.