Interdisciplinary Experience: Vibroacoustics, IT, and Business Development Strategies.

I am an engineer and consultant with over 17 years of experience, specializing in vibroacoustics, software development, and strategic business support. My expertise spans a wide range of industries, from automotive and industrial to IT and e-commerce.

Freelance Projects and Consulting:

- Acoustic Optimization: For Polish manufacturers Reqnet (heat recovery ventilators) and Izzifast (heat pumps, hydraulic cabinets), I reduced the noise level of their products, enhancing their competitiveness.

- Development of Vibroacoustic Processes: At the Israeli startup Aquarius (two-stroke engine-based power generators), I implemented a comprehensive vibroacoustic control process, from concept to production.

- Audits and Improvements: At Inalfa Roof Systems, I conducted an audit and optimization of noise detection processes in automotive sunroofs.

- Software Development: For Foculsy (IT industry), I co-created mobile applications supporting relaxation, meditation, and personal development. I participated in the development of Instalator365 software, streamlining office management for construction companies.

- Environmental Noise Analysis: I performed specialized noise calculations and analyses for various facilities, ensuring compliance with standards.

- Strategic and Marketing Support: I created two winning business plans that secured funding. I led comprehensive marketing strategies for small businesses, including building an e-commerce store in a niche market for custom-made lingerie.

- Before 2010: I carried out acoustics projects for B2B, B2G, and B2C clients, including the development of acoustic maps for two medium-sized cities.

Automotive Industry Experience:

- Nidec Motors & Actuators (Acoustic Quality Engineer): I implemented a crucial improvement in the acoustic control process for electric motors, eliminating subjective operator evaluations. This solution prevented complaints from a key client, Ferrari (knocking steering column), and improved production statistics.

- BorgWarner (NVH Engineer, Research and Development Center): For 7 years, I was responsible for reducing turbocharger noise. As one of the first engineers in the Technical Center, I built and equipped the acoustics department. I tested turbochargers for a wide range of vehicles (from 1.0-2.0L passenger cars to 8-liter truck engines), covering both gasoline and diesel engines. I collaborated with car manufacturers, establishing noise limits and conducting track tests (bearing research, imbalance, the influence of temperatures, pressures, and oil viscosities). I implemented a Lean Startup innovation, replacing costly vehicle tests with component tests, generating significant savings for the company. I trained and implemented three engineers in the turbocharger acoustics development process.

- Chery Europe (NVH Expert): Currently, I am responsible for comprehensive NVH (Noise, Vibration, Harshness) testing of Omoda, Jaecoo, and Exlantix vehicles, including the implementation of active sound technology for electric vehicles. I have participated in two visits to Chinese production plants, which allowed me to work directly with engineers and quickly implement improvements.

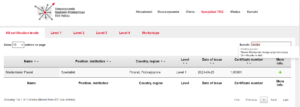

Continuous Development:

I am constantly expanding my knowledge by following the latest trends in acoustics and vibroacoustics. I am particularly interested in psychoacoustics and its impact on sound perception, as well as the development of software and mobile applications. I am a visionary regarding the applications of artificial intelligence, and I believe in its potential for harmony and education.